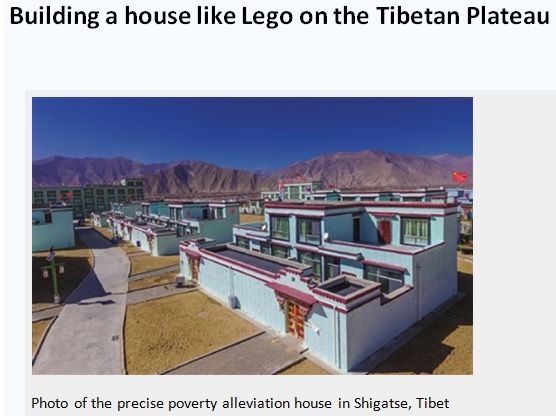

In today’s new era China, every advance has to be called a system, ideally a system born of “top-level design.” Depopulating rural Tibet, to make way for virgin grassland wilderness attractive to Han tourism, is now on such a scale that a new system for mass manufacturing housing for ex-nomads is needed. Officially, this is the “plateau assembled building structure system”, specially designed for Tibet, but its marketers much prefer to liken it to Lego. And as one would expect it is indeed the product of “top-level design”.

This blog has always featured as its masthead a picture of mass housing for former nomads. Chinese cement mixed with Tibetan water, pebbles and sand: it’s so yesterday. Meet the new steel-framed, foam concrete walled new housing for ex-nomads.

One of the leading manufacturers of the new technologies that make it possible to build prefabricated concrete walls for human housing that are lightweight yet strong, points out that the crucial ingredient is the foaming agent: “Standard protein based foaming agents, are made with protein hydrolyzate from animal proteins out of horn, blood, bones of cows, pigs and other remainders of animal carcasses. This leads on the one hand to a very intense stench of such foaming agents on the other hand to a broad range of molecular weight of the proteins because the raw materials are always changing.”

Is this what China’s advocates of prefab resettlement housing are using? They don’t say, but they do emphasize their smart use of other key ingredients which, like hoofs and horns, are usually considered worthless and troublesome waste products. The scientific team demonstrating their prefab foamed concrete houses in Shigatse are proud to make use of a lot of fly ash.

However, there is not a lot of fly ash in Tibet, especially not in TAR or Shigatse, as fly ash is the residue left over after coal is burned to generate electricity. China, which burns more coal than the rest of the world combined, is deep in fly ash, and new uses for it are much needed. The ready availability of fly ash in lowland China is a further reason why construction of all prefab wall panels is done in lowland factories, transported to Tibet, to be bolted together on site.

China has a fly ash problem; Tibet doesn’t. Is this tech a solution to a Tibetan problem? Plenty of oil and gas comes from the Amdo Tsaidam Basin. Less well known is that Qinghai consumes eight million tons of coal a year, overwhelmingly for use in heavy industry.[1]

Prefab sounds good, even virtuous in the public version published in media such as Wen Wei Po (Hong Kong) and Qinghai Scitech Weekly (Xining). But do Tibetans really want to live within lightweight concrete walls made of cattle blood and bones, and of fly ash containing alarming levels of mercury and other toxic substances?

Fly ash is scary stuff, containing “arsenic, beryllium, boron, cadmium, chromium, hexavalent chromium, cobalt, lead, manganese, mercury, molybdenum, selenium, strontium, thallium, and vanadium, along with very small concentrations of dioxins and PAH compounds.” These are good reasons why fly ash as a cheap substitute ingredient in making concrete has seldom been used in human housing.[2]

The foaming agent is the key to this new technology being trialled in Shigatse. Concrete is heavy and dense, so heavy it must be made and poured on the spot. Once in place, if it is not of good quality, it readily cracks and crumbles, a common complaint among Tibetans rehoused in substandard mass housing constructed by Chinese contractors cutting too many corners, skimping on cement powder, putting into the mix too much aggregate crushed rock.

Cement is not only expensive, it is a major cause of climate warming, and China these days uses more cement, pours more concrete, than the rest of the world put together. So it makes sense to find ways of keeping the strength of concrete, while reducing the amount of cement, sand and crushed rock aggregate needed to make it. That is how the use of fly ash and the blood and bones of slaughtered animals came about.

Years ago, engineers experimented with pumping air into liquid concrete, before it sets hard, and showed that concrete suffused with air bubbles can be as strong as the heaviest solid concrete. Only in order to maintain strength, those bubbles of air have to be small, and evenly spread throughout the concrete slurry. That was the difficulty: bubbles tend to clump together and form bigger bubbles which then escape altogether.

How to ensure that bubbles pumped into liquid concrete stay in place long enough for the concrete to set hard? That is a problem only recently solved, and the solution is all those waste organs and bones and blood of slaughtered animals, wastes that no-one wants, that can now be monetised, if you can live with the stench.

As usual, Tibet is the laboratory for Chinese solutions to Chinese problems. As China’s electricity consumption continues to soar, the amount of waste fly ash accumulates. As China’s consumption of meat soars, the amount of hoofs, horns, blood and guts accumulates. Yet again, Tibet becomes a solution for China’s problems.

As nomad relocations have become widespread across Tibet, local communities have learned how to deal assertively with construction contractors, in areas where urbanisation is happening fast, such as Amdo Rebgong. Tibetans these days are better able to spot bad building practices, are better aware of their legal rights as consumers, and better able to speak standard Putonghua Chinese. The result is housing that is built to last.

However, concrete, especially when compared to the flexible nomad black hair woven tent, is not only rigid, it gets very cold in winter and too hot in summer. So the new foamed concrete is meant to be superior, in several ways, not only in being lighter in weight and better suited to large scale factory production.

The new tech is known as foamed concrete, both because the foaming agent enables bubbles to be pumped into the concrete mix, but also because plastic foam is wedged between the concrete outer and inner walls, which makes it lighter, and also better at insulating against extremes of cold and heat. Again, this sounds like a step forward, but the plastic foam is the same as the cladding on many modern buildings around the world which, too late, have been discovered burning all too readily and spreading fire. Foam sandwiched by concrete may be much less hazardous than foam sandwiched between aluminium panels cladding a new building, but no-one can say no hazard exists. This lightweight foamed concrete is better able to withstand earthquakes, compared to standard concrete, but nowhere near as well as the flexible woven yak hair tent.

Yet again, Tibetans are required to inhabit new technologies not in use in lowland China. No-one in Han China is being housed in prefab steel frame houses with foam concrete walls.

Just when Tibetans were getting to grips with how the home building industry with Chinese characteristics actually works, and getting vocational skills to participate in the construction workforce, the game changes. If in future, as in the Shigatse trial, all exnomad housing is made in lowland factories, transported on trucks to be quickly bolted together in Tibet, Tibetans yet again lose agency, yet again are presented with a solution to problems not of their making.

The story promoting this new tech, in Qinghai Scitech Weekly 27 Feb 2019, repeatedly calls the whole process Lego. Like Lego blocks, the appeal is uniformity, centralised mass production, standardised techniques of assembly. For county governments under instruction to fulfil fixed quotas of nomads to be removed from the pasture lands, the appeal is enormous. Housing is just another consumable, can be ordered online, wait for the truck to roll up. The skills needed to bolt together the foamed concrete panels and steel roof are basic, and also standardised.

Like Lego, extra bits can be added on to give the end result a somewhat Tibetan look, even though they no longer serve any structural purpose. A promotional story in English language China Daily is even more enthusiastic, calling it all “fabulous.”

Now that nomad displacement is accelerating, as the declaration of huge new national parks in 2020 gets closer, more and more housing is needed. Out with the old, it is too time-consuming and no Han wants to stay in Tibet through winter: “Traditional house building, cement mixing, on-site pouring, plumb bob measurement, are the norm, but Tibet’s high altitude, high cold, high intensity earthquake and ecological fragile ‘three high and one crisp’ characteristics make the construction of the project more severely restricted by the harsh natural environment.”

The new process was created by Professor Yang Jian from Birmingham University, and Shanghai Jiaotong University’s Building Industrialization Research Team, in a city with plenty of fly ash. His research projects tackle the disadvantages of China’s reliance on concrete, even though frozen concrete is prone to chemical degradation. He notes: “Existing concrete in cold regions is attacked by chloride penetration under freeze-thaw cycles (FTCs). The combined deterioration process accelerate the damage evolution of concrete and reduces the service life of concrete structures.”

Jian Yang is expert in all things concrete, including the dams, highest in the world, planned for the steep mountain rivers of Tibet, due for construction now the lower dams on the Yangtze and Mekong are largely already built.[3]

So is the new “plateau assembled building structure system” the solution? Do Tibetan drogpa nomads want prefabricated kit homes? No-one is asking them. Will the new mass manufactured home interiors be monitored for air quality, for arsenic, beryllium, boron, cadmium, chromium, hexavalent chromium, cobalt, lead, manganese, mercury, molybdenum, selenium, strontium, thallium, and vanadium leaching out of walls and into breathable air? Don’t hold your breath. Do tell Tibetans in Tibet of the hidden dangers.

Foaming concrete, it’s the answer to mass housing of

displaced nomads, a prefab Lego solution to a problem Tibetans never knew they

had, only it’s packed with toxics the promoters don’t mention:

[1] 分行业终端能源消费总量和主要能源品种消费量(2016年)Terminal consumption of energy and major variety energy consumption by sector, Qinghai Statistical Yearbook 2017, table 8-6. So there is plenty of fly ash in Amdo.

[2] Rawaz Kurda, Jose D. Silvestre, Jorge de Brito. Toxicity and environmental and economic performance of fly ash and recycled concrete aggregates use in concrete: A review. Heliyon 4 (2018)